Video-Block

Text-Block

Mission

As we all know, chemistry is the foundation of everything. However, explaining the process of chemical reactions is not a simple task.

How can we transform complex scientific concepts into engaging visual experiences? How do we create an artistic installation that immerses visitors while effectively conveying chemical processing knowledge? These were the key challenges in designing the “Tech Beacon” installation.

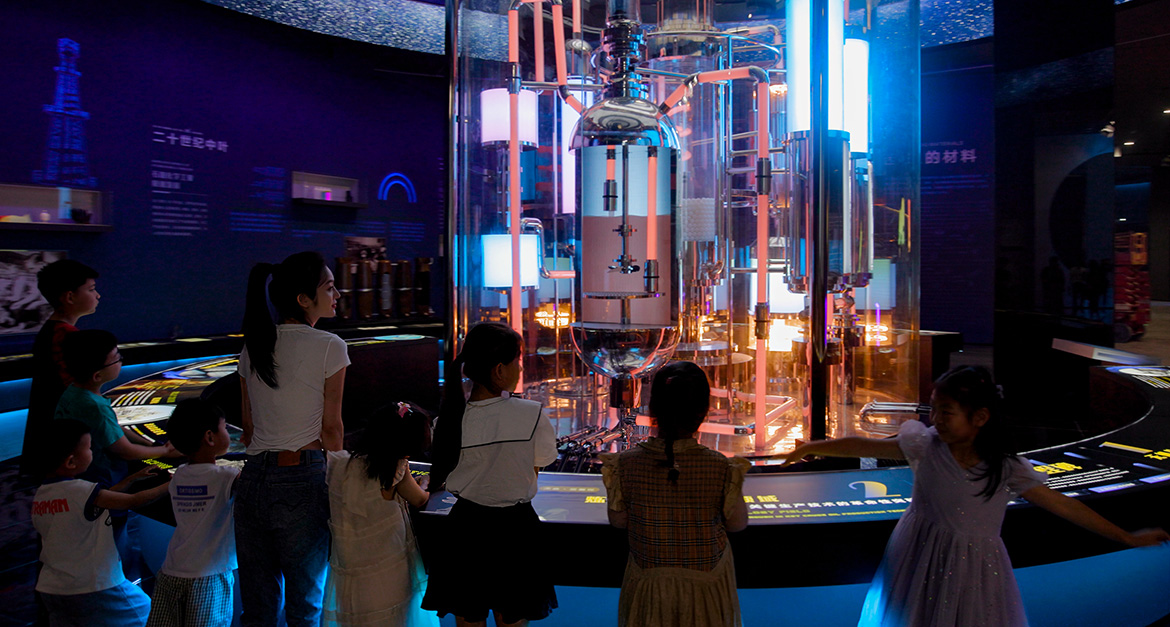

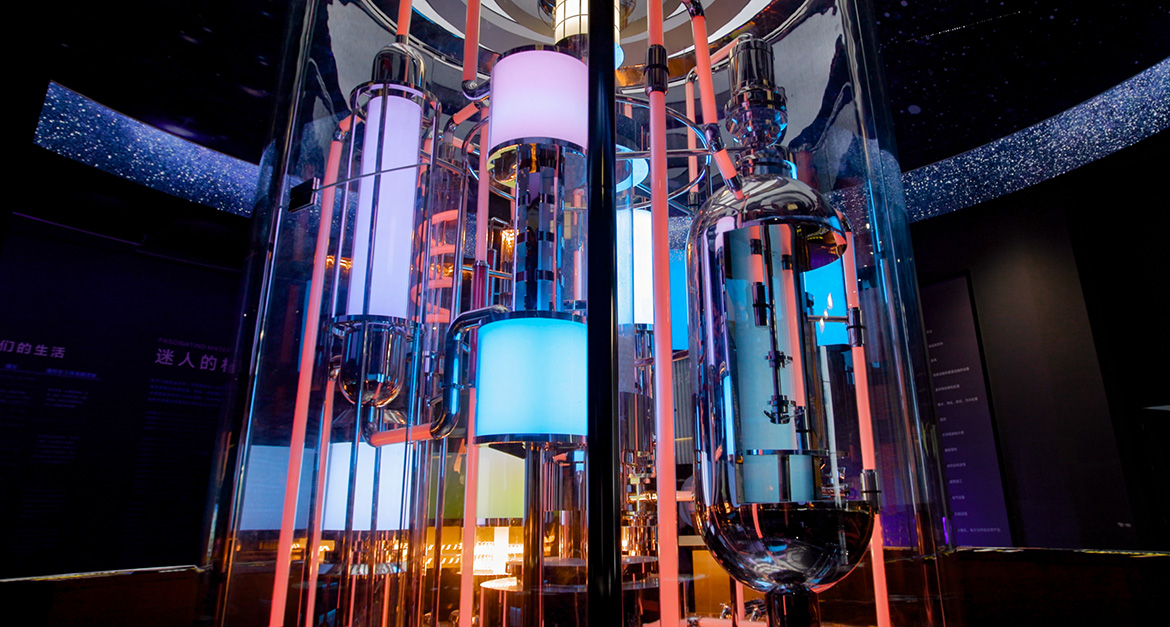

VAVE Studio’s “Tech Beacon” is now open to the public at the Lianyungang Petrochemical Science and Technology Museum. The museum aims to make science accessible, spark curiosity in young minds, and foster a passion for scientific discovery.

Image-Block (JPG/PNG/GIF)

Caption

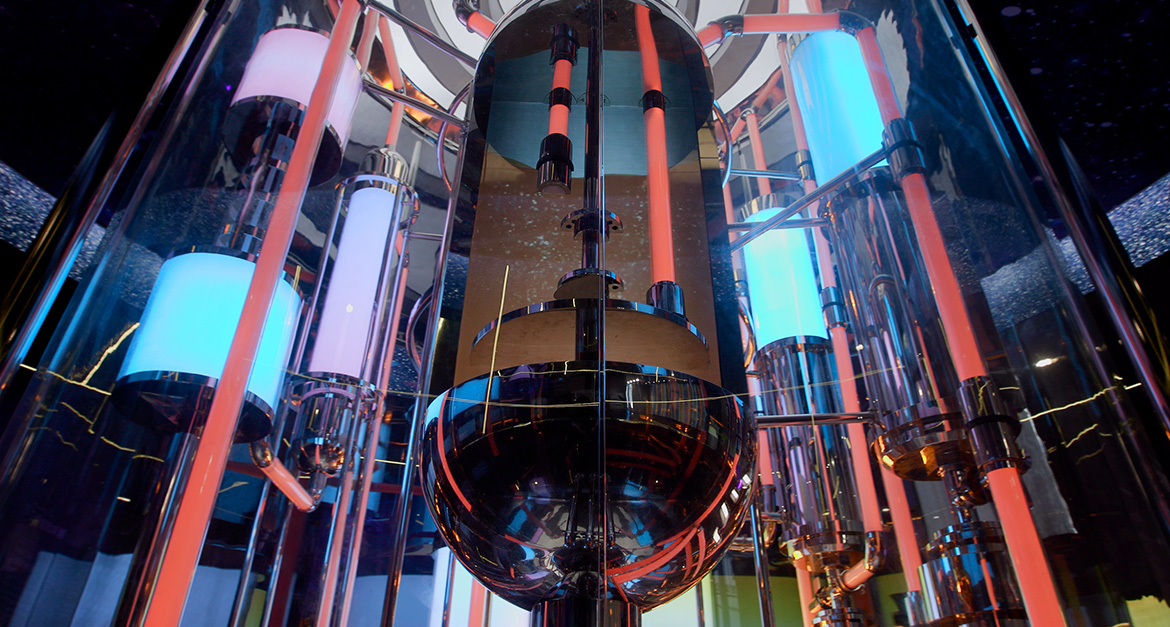

Inspiring view of the 5-meter-tall ‘Tech Beacon’ art installation, blending science and art in a 360-degree immersive experience.

Image-Block (JPG/PNG/GIF)

Caption

Visitors explore the ‘Tech Beacon’ installation, where complex petrochemical processes are brought to life through captivating visual effects and dynamic lighting, making science engaging and accessible.

Text-Block

Idea

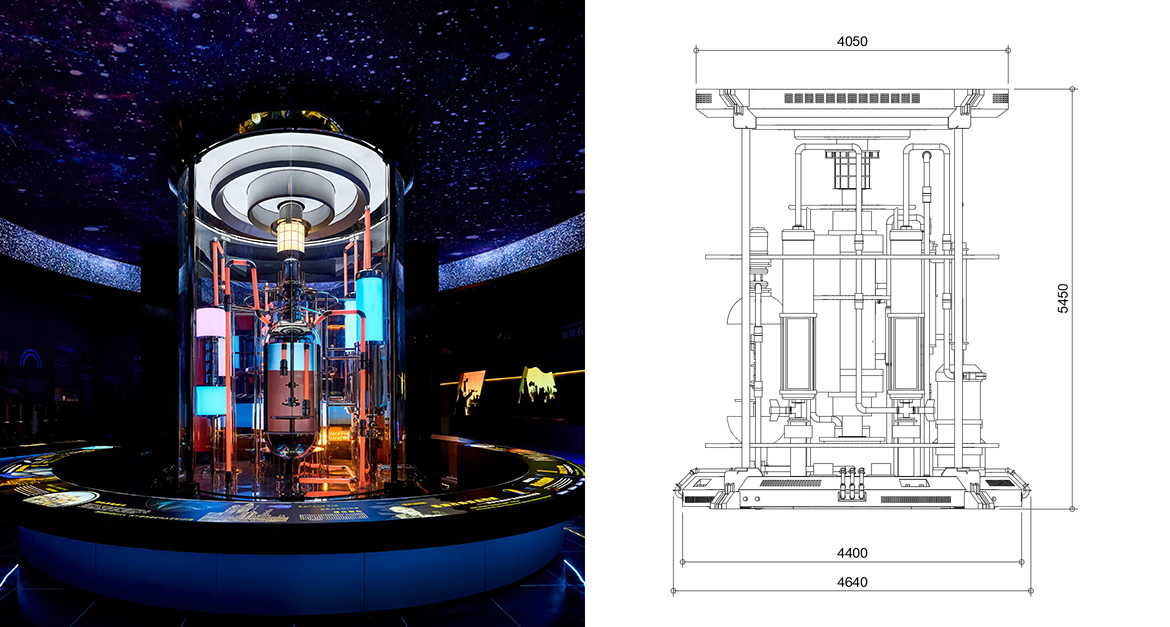

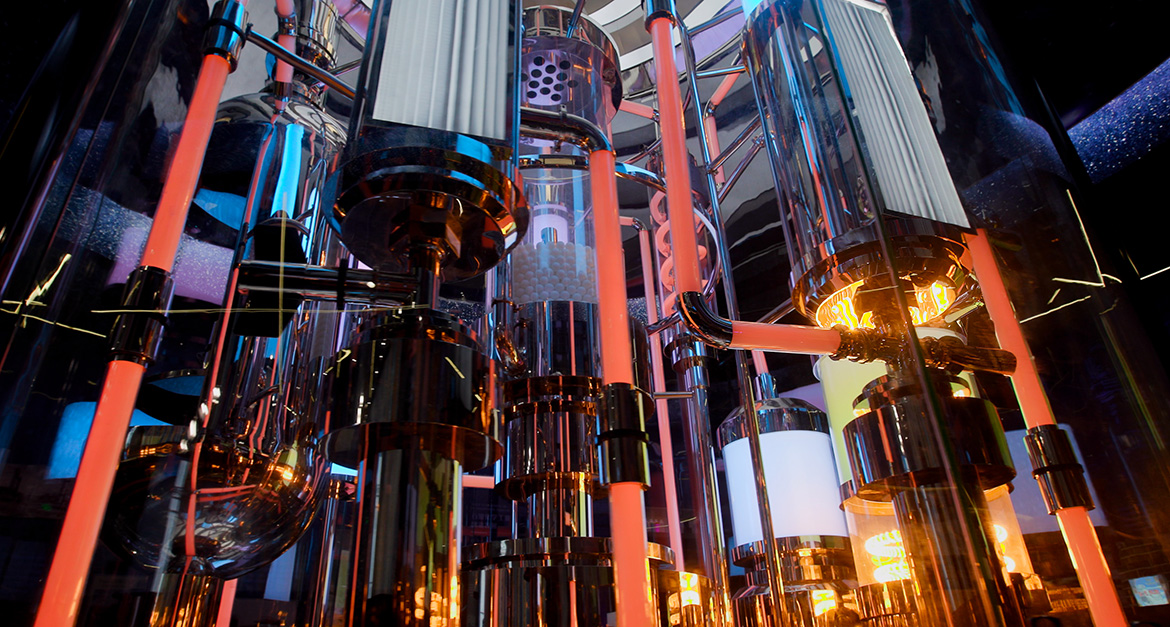

The installation features a 360-degree panoramic design. Through glass panels, visitors can observe five crucial steps in chemical reactions and oil processing from various angles. Based on fundamental chemistry principles, the installation focuses on four common processes: filtration, distillation, extraction, and polymerization. It also showcases the pelletizing of polystyrene, a key material in plastics production. Dynamic lighting and visual effects illustrate liquid flows and purity changes, captivating visitors’ attention.

Step 1: Filtration The initial solution flows through two filter cartridges, removing impurities. Flat light panels at the bottom of the cartridges showcase the filter media. Two “discharge ports” are located at the conduit’s end.

Step 2: Distillation Filtered solution vaporizes via spiral heating elements. The vapor rises in a tank, passes through filters and pipes, and collects in a storage tank. Dynamic lighting reflects the liquid level changes, demonstrating the distillation process.

Step 3: Extraction This step illustrates how specific chemicals are separated by adding reagents, causing layering due to density differences. Materials from previous steps enter a separation tube through distinct feed pipes, then flow into separate storage tanks.

Step 4: Polymerization Polymerization is a means of fully blending different chemicals through physical agitation and causing chemical reactions. A liquid feed pipe and a gas inlet converge in a stirring tube, simulating gas-liquid polymerization. Fine bubbles rise and swirl from the bottom, with the final product exiting through a lower outlet.

Step 5: Pelletizing The final step in polystyrene processing is represented by white EVA balls falling and collecting, simulating material solidification and collection.

Image-Block (JPG/PNG/GIF)

Caption

On the left, the ‘Tech Beacon’ installation in action; on the right, a detailed technical drawing, showcasing the intricate design and scientific principles behind the immersive experience.

Text-Block

Solution

Rich, colorful lighting effects vividly depict liquid flows and purity changes in oil processing. This transforms complex petrochemical concepts into an accessible, visual experience. Standing 5 meters tall, the installation creates a sense of awe while remaining approachable. Its high-tech structural details evoke industrial aesthetics, blending science with art. The “Tech Beacon” succeeds in making petrochemical processes tangible and engaging, offering visitors a unique, immersive learning experience that bridges the gap between complex science and public understanding.

Image-Block (JPG/PNG/GIF)

Caption

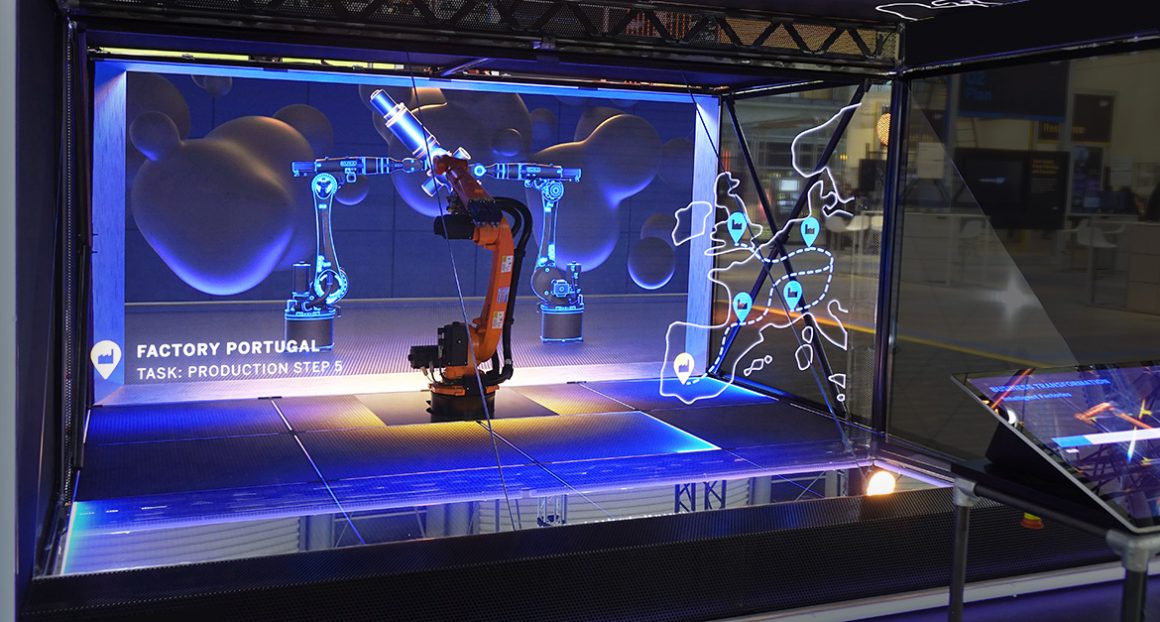

On-screen animation of the gas-liquid polymerization process: fine bubbles rise and swirl, while dynamic lighting highlights liquid flows, distillation, and the movement of chemical reactions through tubes, conduits, and reservoirs, bringing the science behind petrochemical processes to life.

Image-Block (JPG/PNG/GIF)

Caption

Detailed view of the Extraction: This step illustrates how specific chemicals are separated by adding reagents, causing layering due to density differences. Materials from previous steps enter a separation tube through distinct feed pipes, then flow into separate storage tanks.

Image-Block (JPG/PNG/GIF)

Caption

Close up view of the light installation inside the installation.